Introduction In the ever-evolving world of outdoor gear and clothing, the fabric used for wind coats and jackets plays a crucial role in ensuring both comfort and protection. Whether you’re an adventu...

View MoreOutdoor enthusiasts know that the right gear can make all the difference between a pleasant adventure and a difficult one. As more people turn to outdoor activities, the demand for advanced materials ...

View MoreFour way stretch elastic fabrics are popular for their versatility, comfort, and durability. These fabrics are used across multiple industries, including apparel, sportswear, medical textiles, and hom...

View More

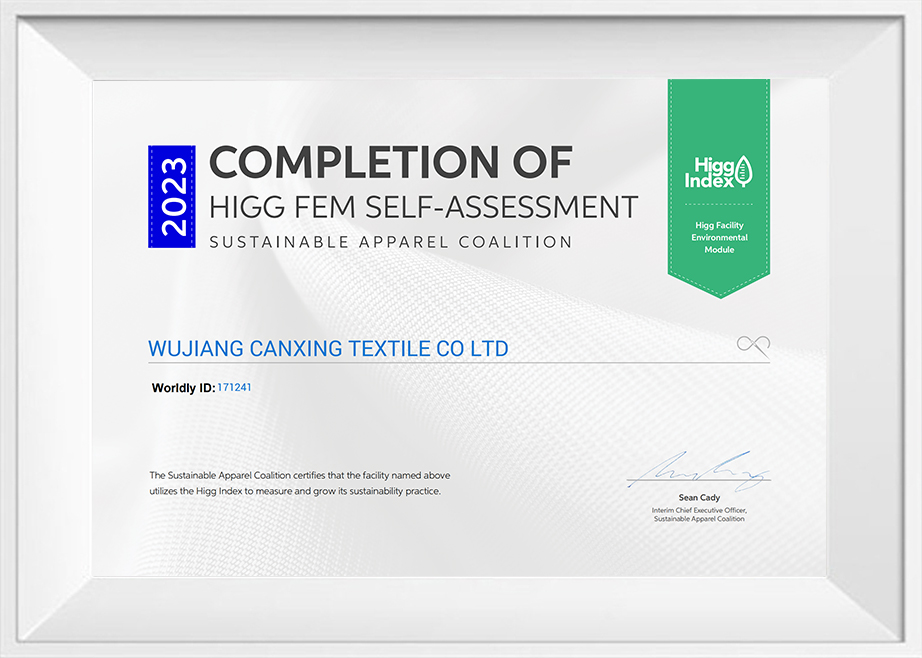

Wujiang Canxing Textile Co., Ltd., with its profound background and advanced technology in the textile field, not only has a variety of finishing processes including dyeing, printing, and casting, but also ensures that we can flexibly respond to the diverse needs of the market and develop various special products. More importantly, the company's own textile factory enables us to directly control the production process, ensuring the price advantage and excellent quality of the products from the source.

In the production of polyester Oxford cloth, we have demonstrated unique technological advantages. The reason why polyester Oxford cloth can achieve a variety of weaving effects such as twill, full stretch, low stretch and twill with embossed pattern is mainly due to the exquisite craftsmanship in the following aspects:

Advanced weaving equipment: The company has introduced internationally leading weaving equipment, which has high automation and precise control capabilities, and can accurately adjust the interweaving method of warp and weft yarns, so as to easily weave complex textures such as twill and embossed pattern. At the same time, the high precision of the equipment also ensures the uniformity and stability of the fabric structure.

Professional process design: Our R&D team has rich knowledge and practical experience in textile engineering, and can design scientific and reasonable weaving process solutions according to market demand. For fabrics with different elastic requirements such as full elasticity and low elasticity, we ensure that the fabrics achieve the expected elastic effect by adjusting the elastic component ratio of the yarn, weaving tension, and stretching and shaping in the finishing process.

Fine finishing technology: After weaving, we will also perform a series of fine finishing treatments on the fabrics, such as pre-shrinking, shaping, dyeing, printing, etc. These processes not only improve the appearance quality of the fabrics, such as color vividness and pattern clarity, but also further enhance the physical properties of the fabrics through specific processing methods, such as wear resistance, scratch resistance, wrinkle resistance and tear strength. In particular, for fabrics with embossed twill, we use special embossing or three-dimensional printing technology to form a unique concave and convex texture on the surface of the fabric, which increases the three-dimensional sense and layering of the fabric.

Wujiang Canxing Textile Co., Ltd. has successfully realized the flexible conversion of polyester Oxford fabrics in various weaving effects such as twill, full elastic, low elastic and twill with convex pattern through advanced weaving equipment, professional process design and fine finishing technology, meeting the diverse needs of different customers in the market. At the same time, the preferential prices and high-quality products we directly provide allow every customer to enjoy a shopping experience that is worth the money.

What special precautions or technical requirements are there for the application of printing technology on polyester Oxford fabric?

At Wujiang Canxing Textile Co., Ltd., we not only have a diversified finishing process system covering dyeing, printing, and casting and rolling, but also can flexibly respond to the diverse needs of different customers, develop and produce high-quality products that meet or even exceed their expectations, and also demonstrate outstanding technical strength and market adaptability in the field of polyester Oxford fabric, a commonly used and cost-effective fabric.

Regarding the application of printing technology on polyester Oxford fabric, which is specifically mentioned in the company's advantages, we follow a series of special precautions and technical requirements to ensure the excellent quality and market competitiveness of the final product:

Material adaptability assessment: First, we will select matching inks and printing technologies based on the physical properties (such as wear resistance, scratch resistance, elasticity) and chemical stability of polyester Oxford fabric. Ensure that the selected material will not fade, deform or affect the original excellent properties of the fabric due to chemical reactions during the printing process.

Pretreatment process: To improve the printing effect, we will perform necessary pretreatment on polyester Oxford cloth, such as degreasing, decontamination, humidification or sizing, to enhance the adhesion and color saturation of the ink, while reducing the color difference and blurring during the printing process.

Accurate alignment and color registration: Polyester Oxford cloth is often used to make products such as bags that require high pattern accuracy. Therefore, we use advanced alignment systems and color registration technology during the printing process to ensure the precise alignment and color consistency of the pattern to meet the aesthetic and functional needs of the high-end market.

Environmental protection and durability considerations: In view of the current market's increasing attention to environmentally friendly products, we use environmentally friendly inks and additives to ensure that the printing process and finished products meet international environmental standards. At the same time, by optimizing the printing process and improving the wear resistance and washability of the pattern, the polyester Oxford cloth products can still maintain clear patterns and bright colors during long-term use.

Personalized customization service: Relying on a strong technical team and flexible production line, we can provide one-stop personalized customization services from design to production according to the specific needs of customers, including but not limited to special textures, gradient colors, complex patterns and other printing effects, to meet the diverse needs of different customer groups in the market.

Wujiang Canxing Textile Co., Ltd. not only focuses on the advanced technology and environmental protection in the printing process of polyester Oxford cloth, but also emphasizes the precise grasp and personalized satisfaction of customer needs, so as to stand out in the fierce market competition and provide high-quality and cost-effective textile products to global customers.